Forged Wind Turbine Gear Blank

description2

DESCRIPTION

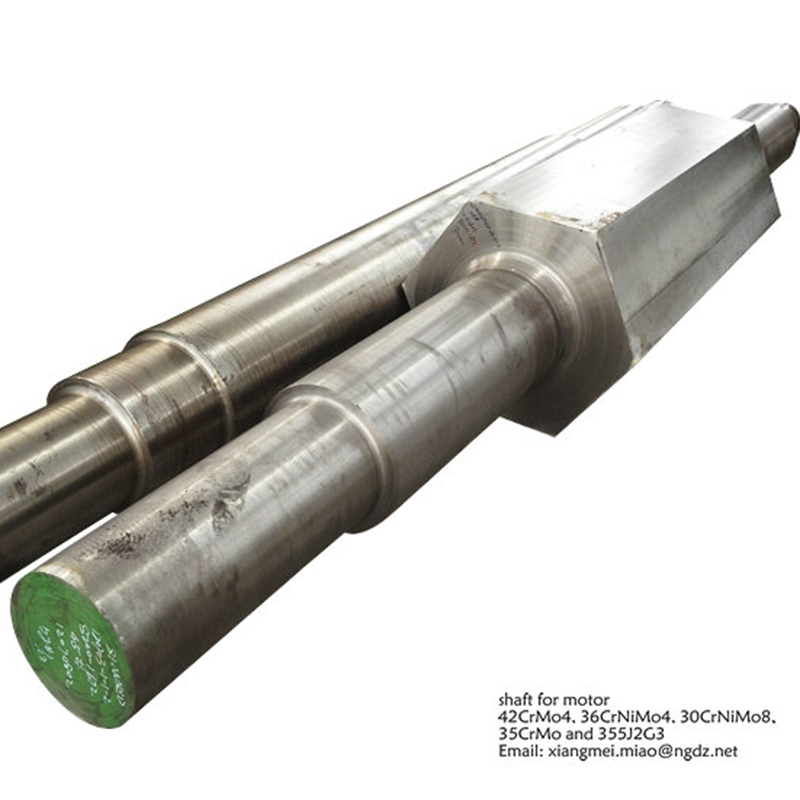

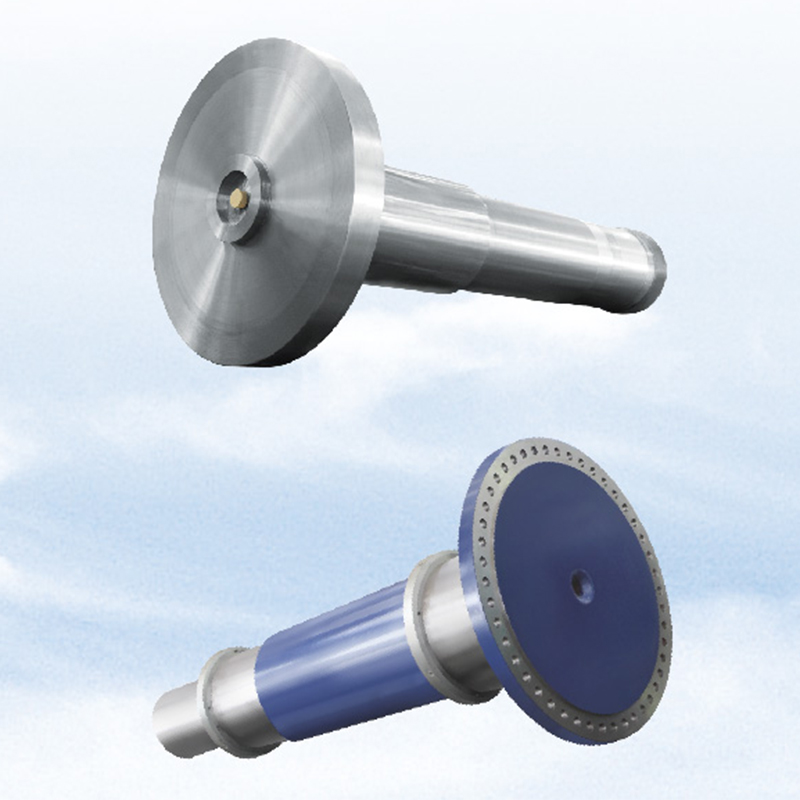

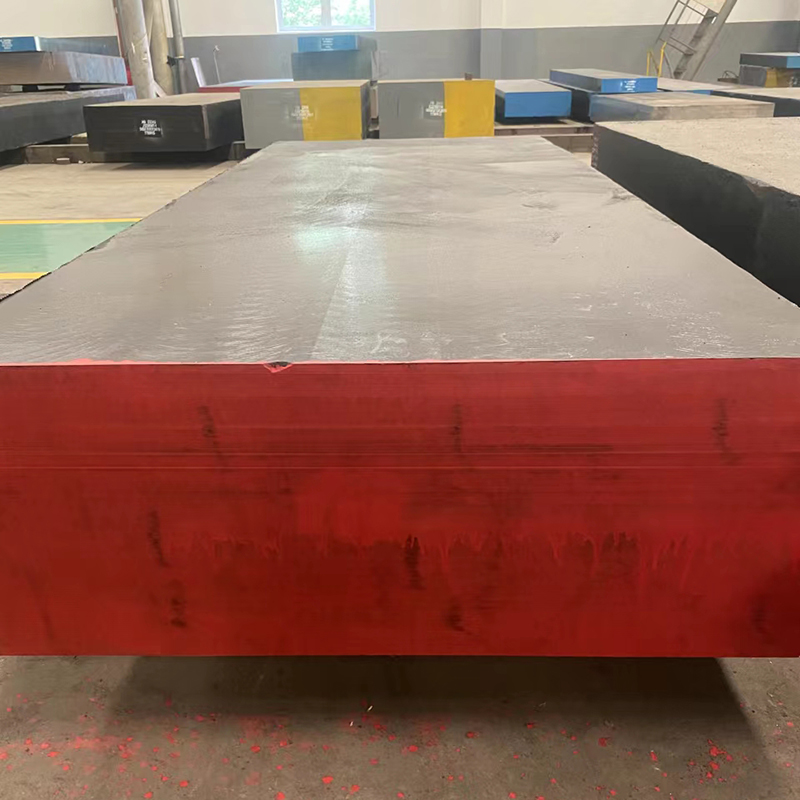

The materials used for wind turbine gear blanks typically include high-performance alloys such as steels and ceramics.Our products are mainly made of high-strength alloys and low-alloy steels with excellent mechanical properties, ensuring reliable performance under harsh operating conditions.Our manufacturing process involves a comprehensive selection of raw materials,smelting, precise forging, heat treatment, surface treatment, and quality control. We use modern forging machines and advanced production technologies to ensure the dimensional accuracy and mechanical properties of each gear blank.During the production process, Forging Factory adheres to strict quality standards and implements a rigorous quality control system. Our skilled technicians and engineers are responsible for ensuring that every gear blank meets the highest quality requirements, delivering outstanding performance and durability.Forging Factory Wind Turbine Gear Blanks offer a number of competitive advantages, making them the preferred choice for our clients. Their load capacity is significantly higher than that of cast and forged gears, while their tooth contact stress and bending stress are lower, resulting in less wear and tear.In addition, our gear blanks are processed using Forging Factory's patented surface treatment technology, which ensures that their surface hardness, tensile strength, and compressive residual stress meet or exceed industry standards. This contributes to their excellent fatigue strength, torsional strength, and bending strength, making them highly suitable for use in wind turbines.If you are looking for a reliable partner to supply high-quality wind turbine gear blanks, Forging Factory is here to help. Contact us today to discuss your specific requirements and learn how we can collaborate to meet your objectives.