0102030405

Metallurgical Machinery Forgings

description2

DESCRIPTION

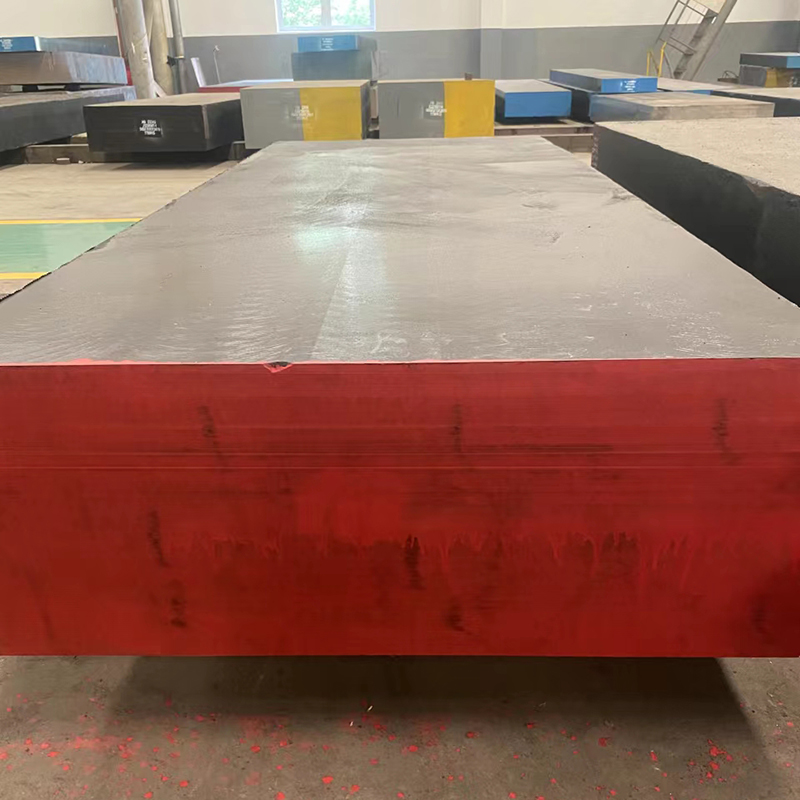

With our products, you can expect superior craftsmanship and reliability. Each forging is manufactured to industry-leading material standards such as EN10083, EN10084, EN10085, EN10088 and EN10250, ensuring the highest quality benchmarks are met. Our forgings’ raw material are produced using advanced technologies such as EAF+LF+VD+ingot casting (bottom casting), and the final product is strong and reliable.

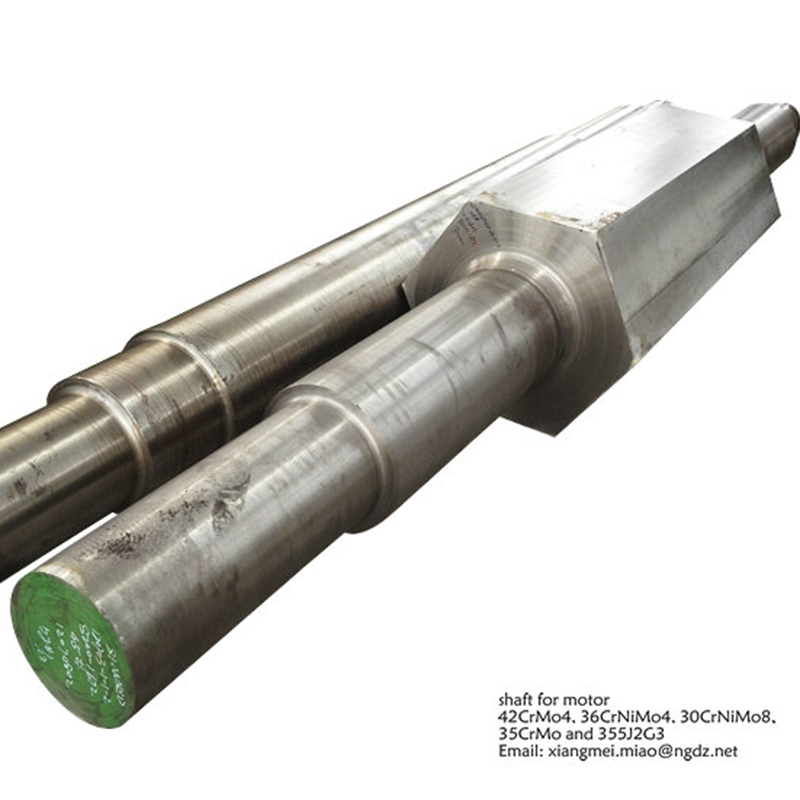

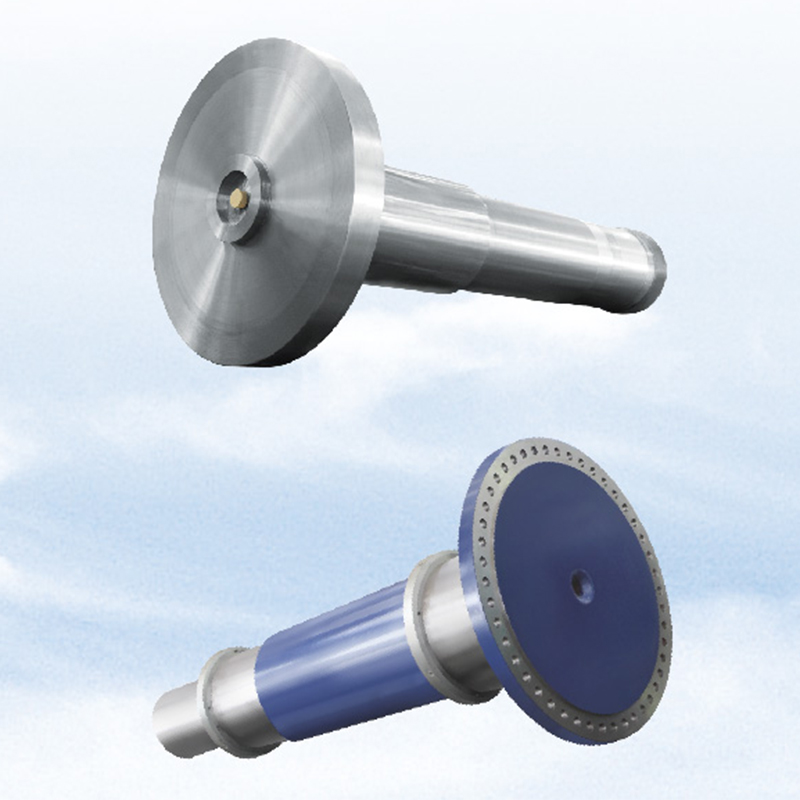

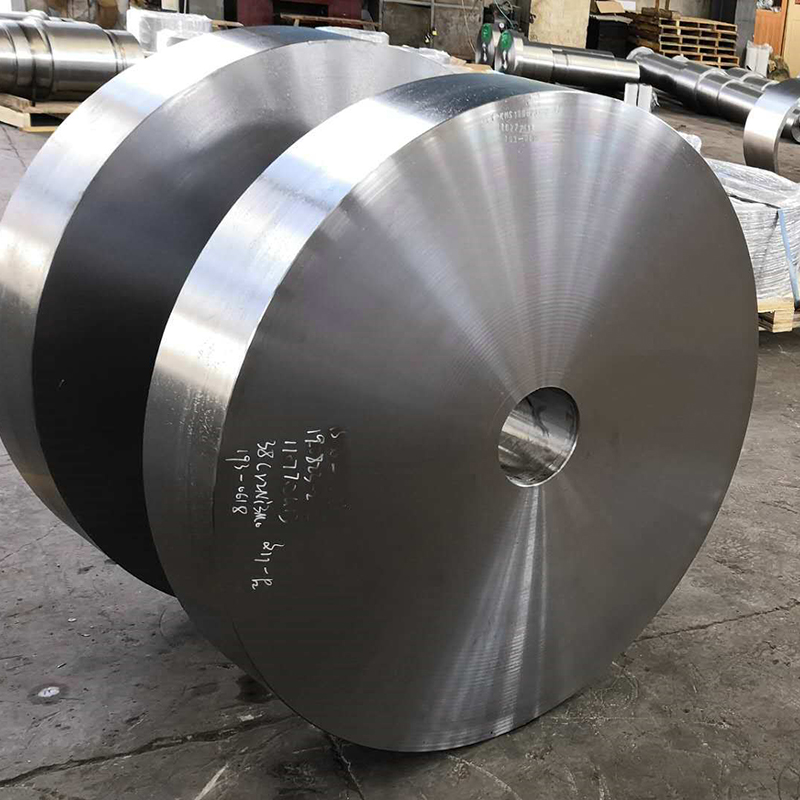

Our metallurgical machinery forgings have a wide range of applications. Whether you need rotors, shafts, rollers, crankshafts, spindles, eccentric shafts, bevel gears, gears, parallel pinions, flanges, crowns, bushings, sleeves, couplings or crank arms, we have you covered needs. Our extensive product range ensures that we can meet all your specific requirements, no matter how complex they may be.

One of the key characteristics of our metallurgical machinery forgings is the forging ratio. Our forgings are produced with a precision and accuracy of at least 3:1 or better. This ensures optimal structural integrity and improves the overall performance of the finished product.

In order to further improve the strength and durability of forgings, we undergo a strict heat treatment process. This includes normalizing, quenching and tempering, solution treatment of stainless steel or stress relief of the rotor or shaft. These processes help create a uniform and consistent metallographic structure, resulting in forgings that are highly resistant to cracking, spalling, shrinkage cavities, pinholes and welding problems.

In order to ensure the quality of forgings, we comply with ASTM E45 metallographic structure standards. This ensures a grain size of 5 or better, indicating a fine and uniform microstructure. We take great pride in providing forgings that are free of defects and imperfections, giving you peace of mind that our products will perform outstandingly in your application.

Overall, our metallurgical machinery forgings demonstrate our commitment to delivering superior quality and performance. With a wide range of applications, high-quality materials, precise manufacturing techniques and extensive quality control measures, our forgings are the best choice for any metallurgical machinery requirement. Choose our forgings and experience the difference in performance and reliability.