Crankshaft Forging Process: Benefits and Steps Explained

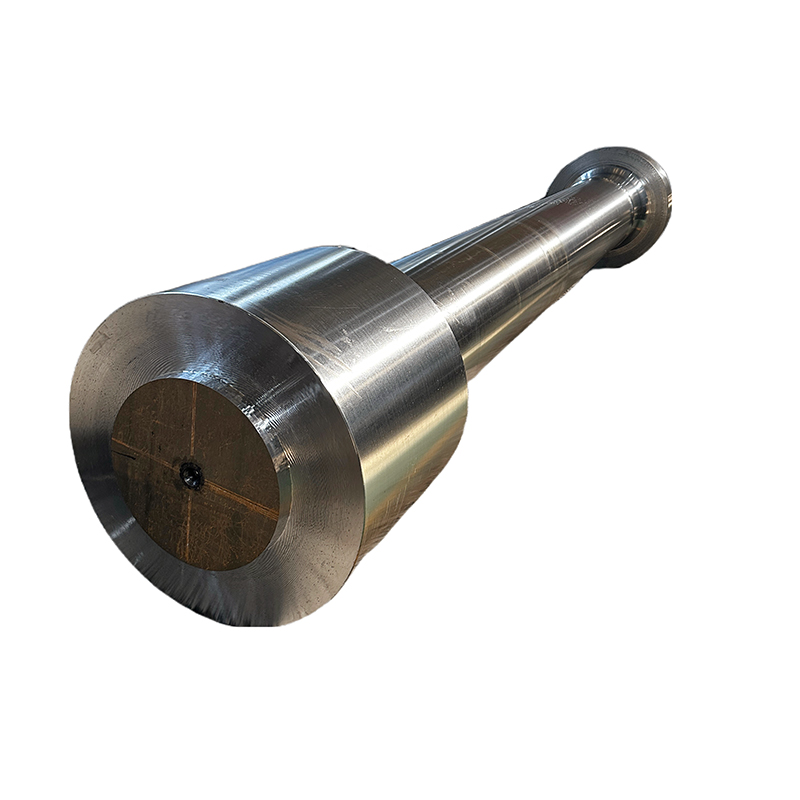

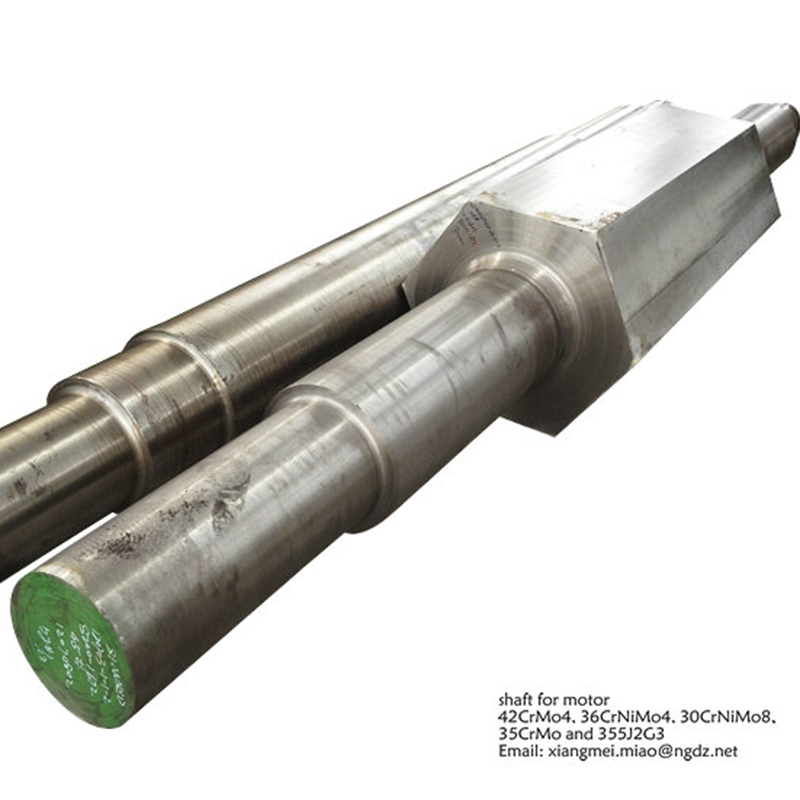

Jiangyin Nangong Forging Co., Ltd. specializes in the production of high-quality crankshafts through a precision forging process. Our crankshafts are manufactured using top-grade materials and advanced forging techniques, ensuring excellent mechanical properties and dimensional accuracy, The crankshaft forging process involves the use of high-pressure to shape the metal into the desired form, resulting in a product that is strong, durable, and able to withstand the rigors of engine operation. Our company utilizes state-of-the-art equipment and skilled technicians to ensure that each crankshaft meets the highest standards of quality and performance, Our crankshafts are designed to meet the requirements of various applications, including automotive, marine, and industrial engines. Whether you need a standard crankshaft or a custom-designed solution, Jiangyin Nangong Forging Co., Ltd. can provide a reliable and cost-effective solution for your specific needs, With a focus on quality, reliability, and customer satisfaction, our company strives to deliver crankshafts that surpass industry standards and exceed customer expectations. Choose Jiangyin Nangong Forging Co., Ltd. for all your crankshaft forging needs

- Flange Joint Manufacturers

- Bevel Gear Exporters

- Worm Gear Exporters

- Forged Powdered Metal Connecting Rods Manufacturer

- Shaft Driven Generator Manufacturers

- High-Quality Welding Gear

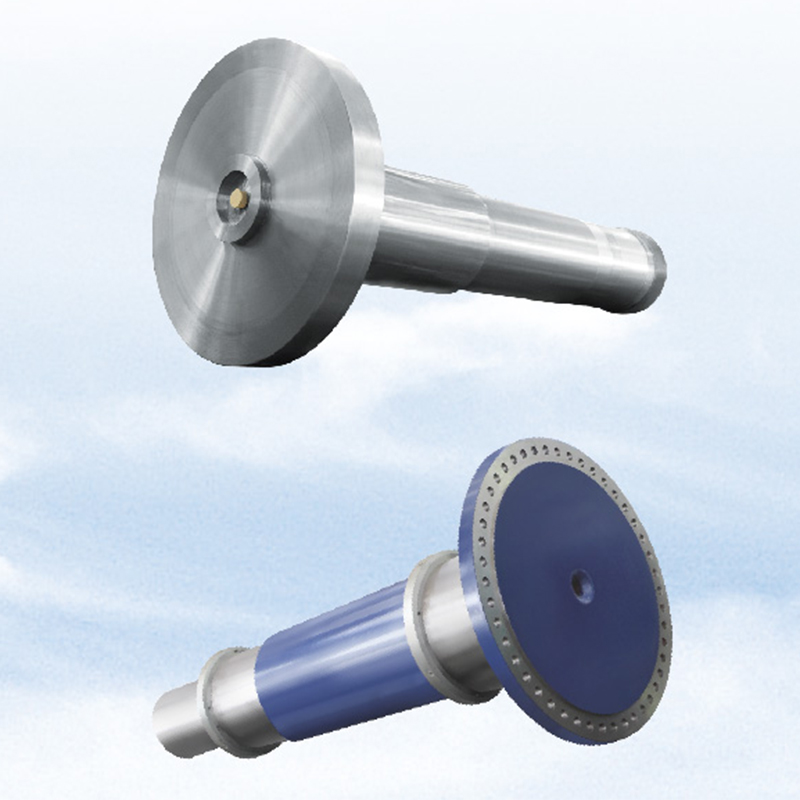

- High-Quality Shaft In Turbine

- Forged Steel Gate Valves Quotes

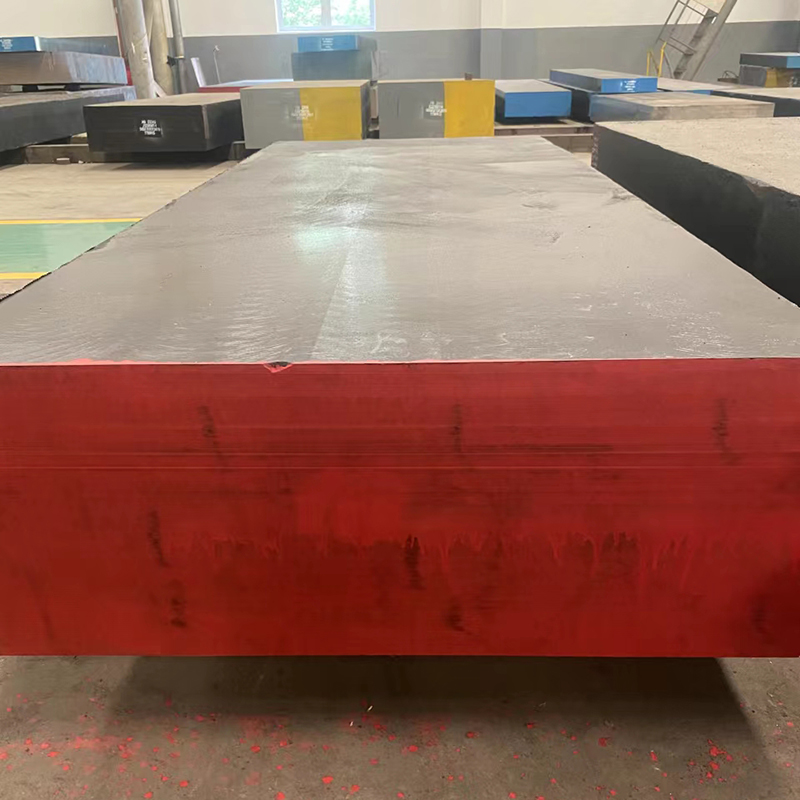

- S355j2g3 Cylinder Block Pricelist

- Engine Valve Body Supplier